Customised steam turbines

MoreSteamEfficiencyIndividualitySustainability

For your energy project.

We are M+M

Your Expert for Steam Turbines.

For over 25 years, M+M Turbinen-Technik GmbH has specialized in the design and manufacturing of steam turbines for energy recovery. As a family-owned company, we place great emphasis on quality, partnership, reliability, and individuality. Our team consists of brilliant minds who passionately apply their collective knowledge and years of expertise to provide customized turbine solutions.

We manufacture steam turbine packages according to your specific requirements and needs, maximising efficiency from your existing steam potential.

The advantage is clear: you generate sustainable energy on your own terms, becoming less reliant on energy suppliers and rising electricity prices, regardless of when and where.

We accompany you on the path to a sustainable future.

200 +

Realised Projects

0.2 – 30 MWe

Power Range

3

Sales Offices

Customer References Worldwide

The success of our turbine generator sets is something to be proud of. Across all industries, we continue to deliver quality customised solutions for our clients.

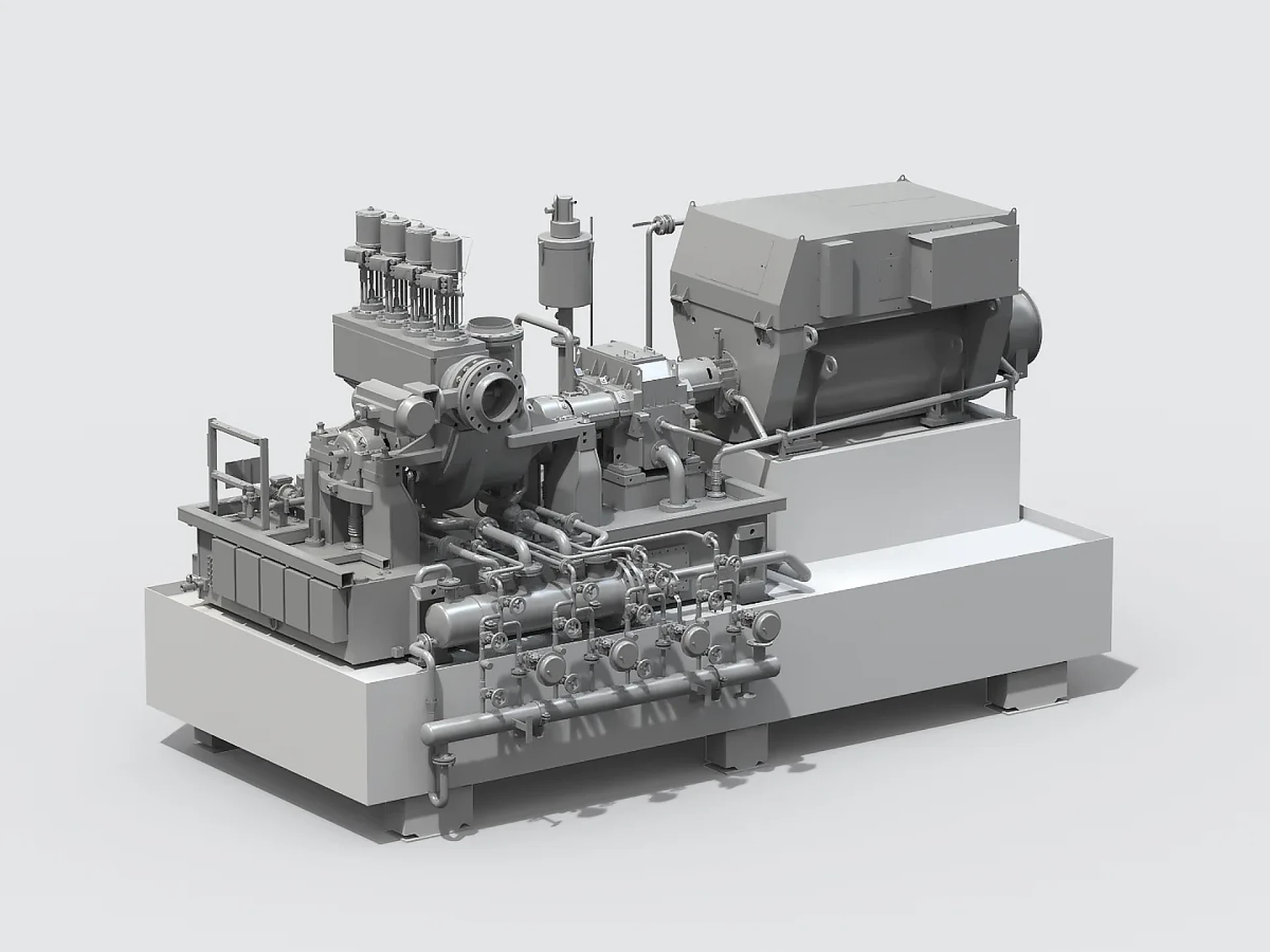

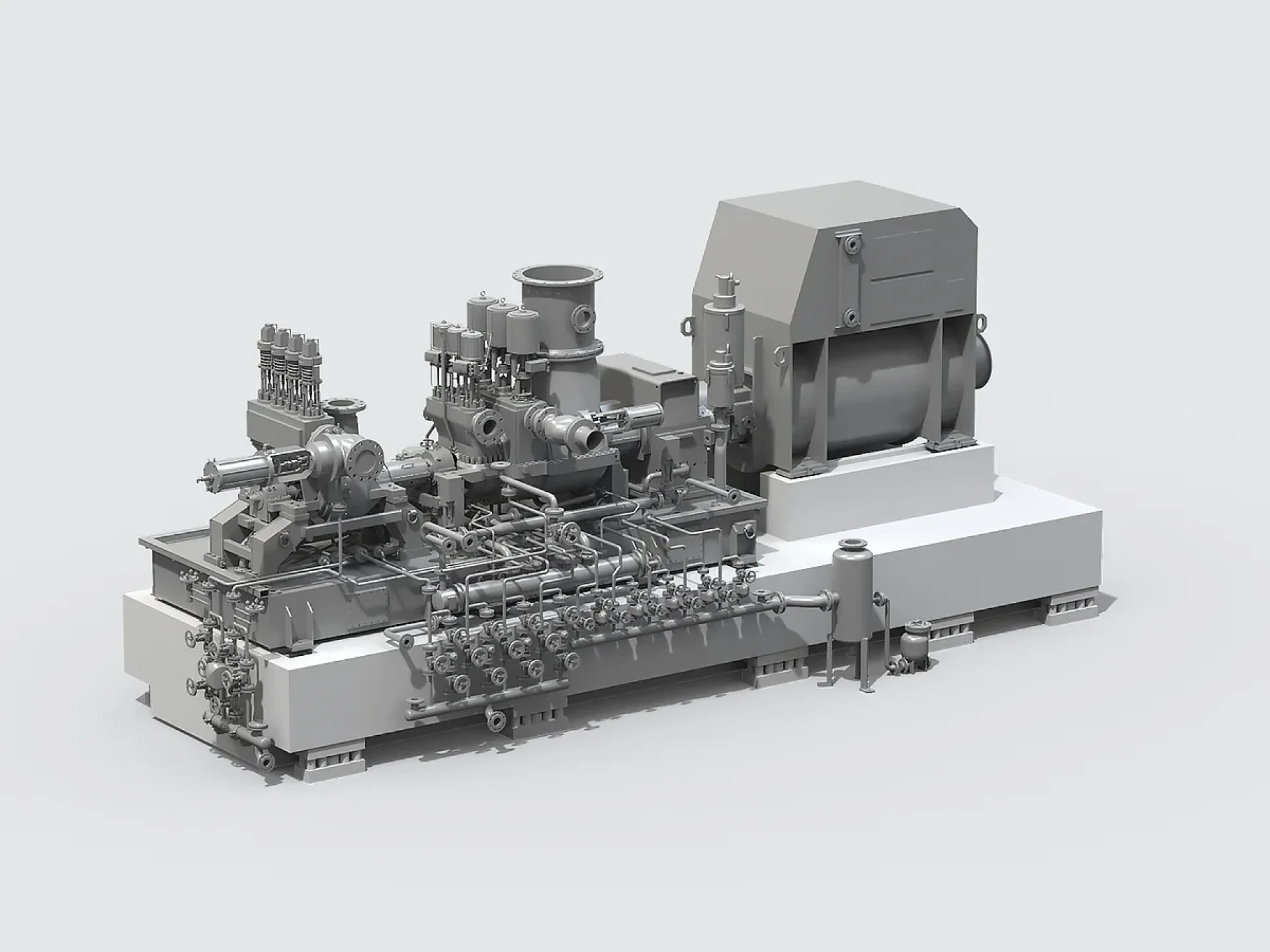

Our Steam Turbines

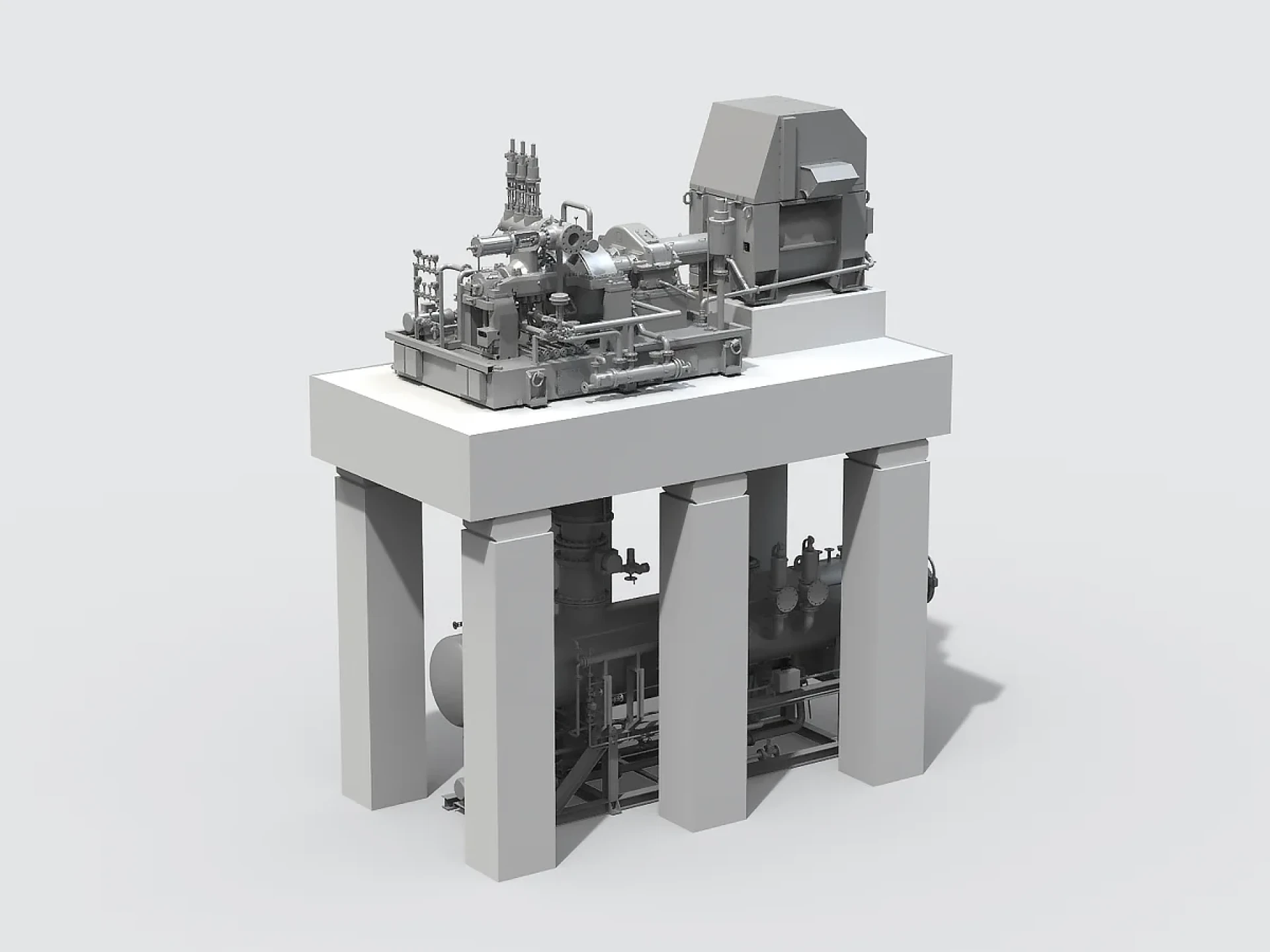

Backpressure Turbine

Optimizing the use of your process steam with combined heat and power production.

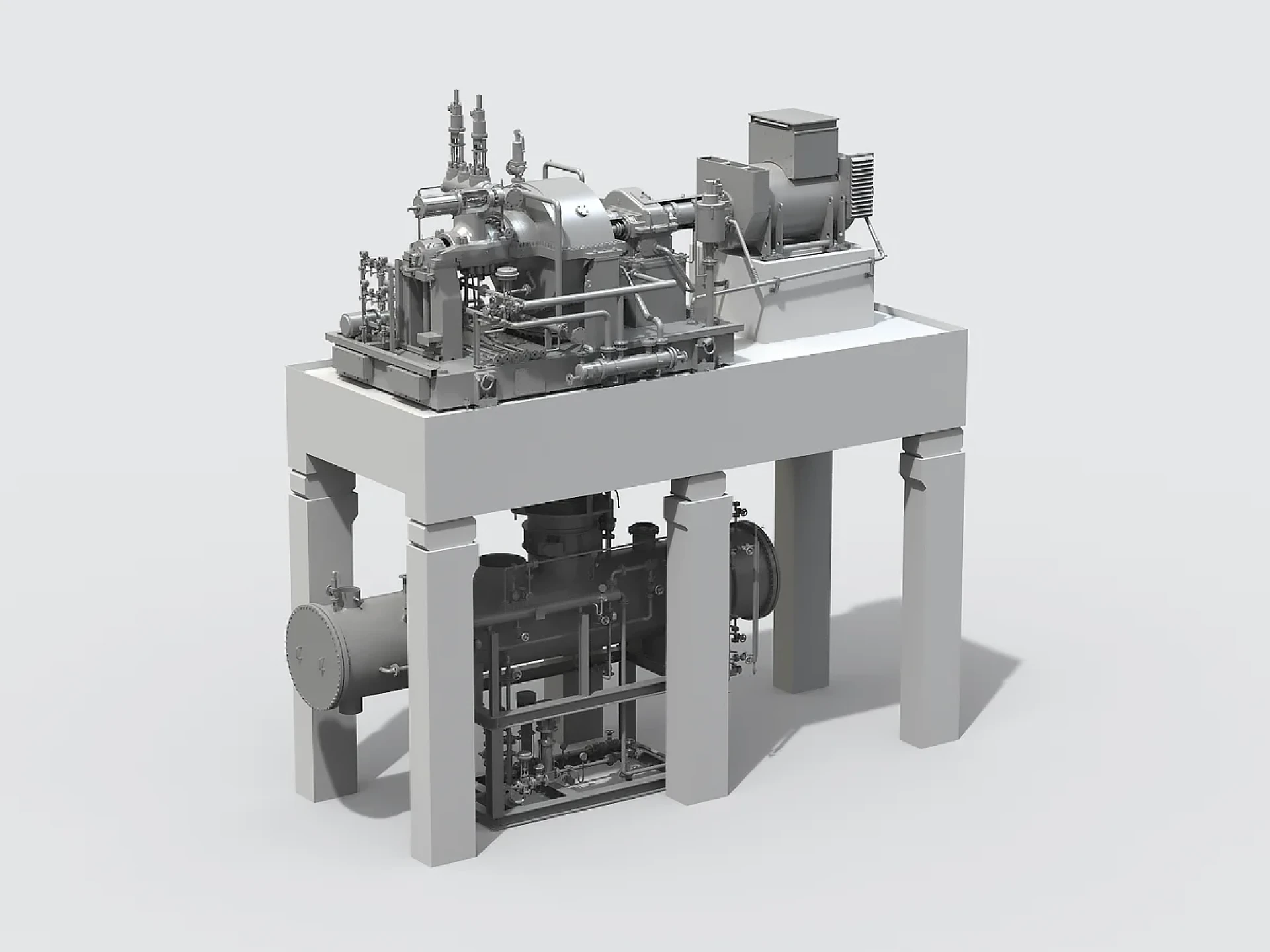

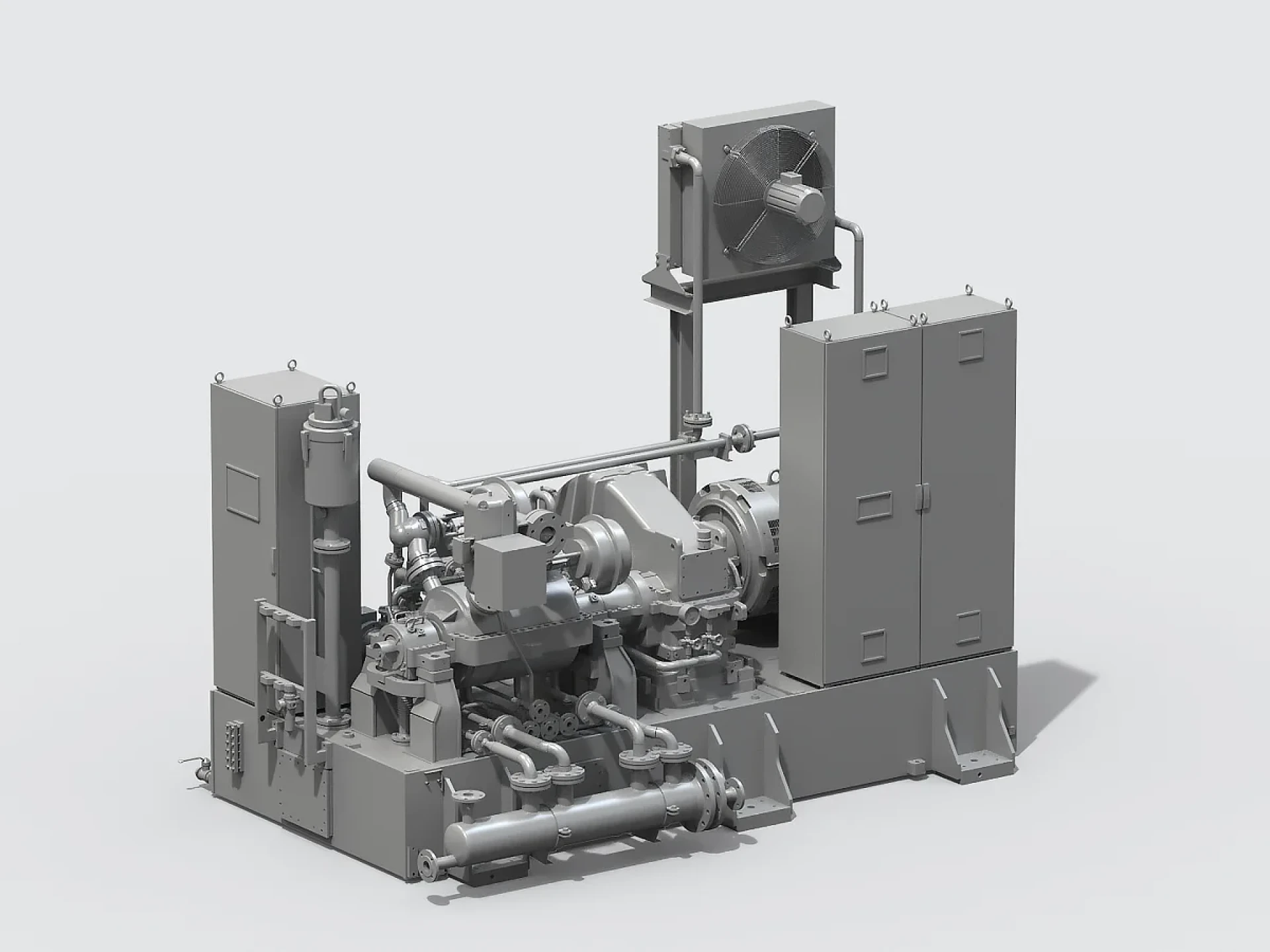

Condensing Turbine

Maximum power generation from your steam with optimal efficiency.

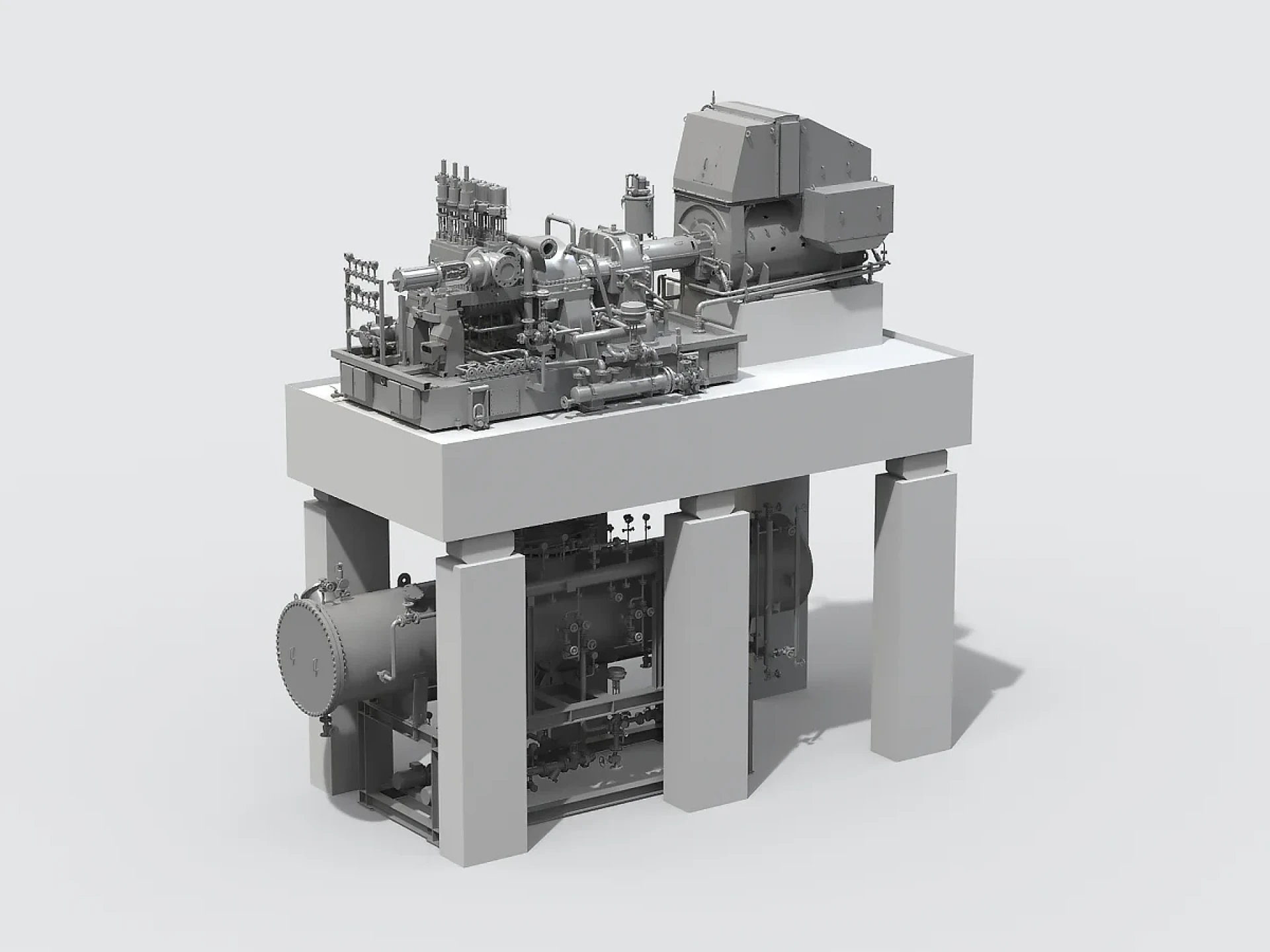

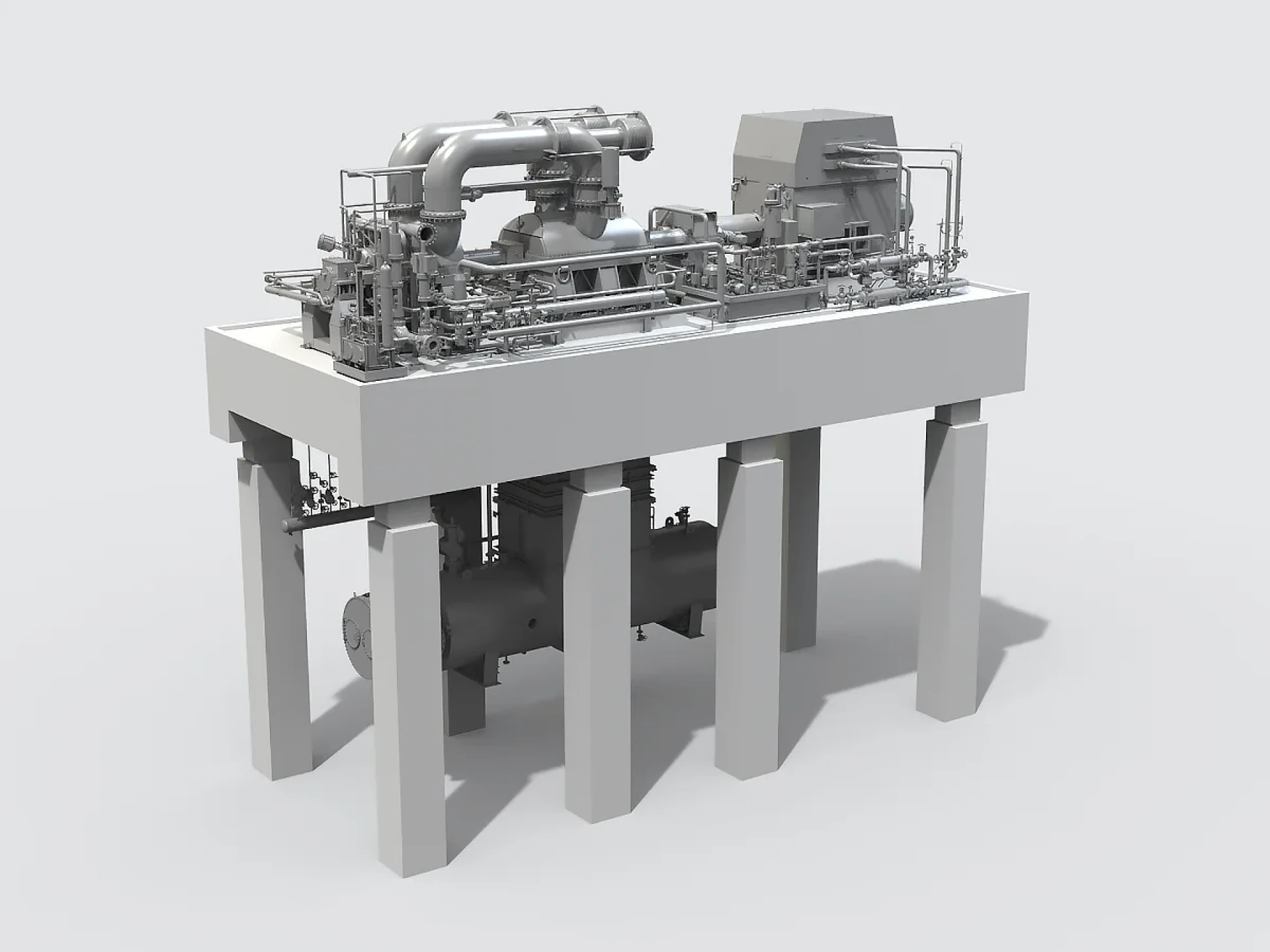

Extraction Turbine

Optimal Process Integration with our M+M Extraction Turbine.

Induction Turbine

Power generation with steam supply from multiple pressure levels.

District-Heating (CHP) Turbine

Combined heat and power (CHP) for optimal energy utilisation.

Mini-Turbine

Optimal efficiencies: Even with minimal steamflow.

M+M Specials

The turbines that no one else builds.

Innovations are the key to our success. Each turbine is tailored to your project and adapted to the site conditions both in terms of design and thermodynamics.

Backpressure Turbine

Optimizing the use of your process steam with combined heat and power production.

Condensing Turbine

Maximum power generation from your steam with optimal efficiency.

Extraction Turbine

Optimal Process Integration with our M+M Extraction Turbine.

Induction Turbine

Power generation with steam supply from multiple pressure levels.

District-Heating (CHP) Turbine

Combined heat and power (CHP) for optimal energy utilisation.

Mini-Turbine

Optimal efficiencies: Even with minimal steamflow.

M+M Specials

The turbines that no one else builds.

Your All-in-One Service Provider

We deliver the highest quality, including personalised and individual support.

All of our turbines include a customized service and maintenance package, ensuring our customers benefit from not only high efficiency, but also fast response and maximum availability – over the entire plant lifecycle.

Maintenance

Ensure a high degree of turbine availability with proper maintenance.

learn more

Upgrades

Adapting to changing conditions, to achieve higher efficiency or improved power outputs.

learn more

Spare Parts Management

Our spare part service provides a reliable and frictionless supply of spare parts.

learn more

Technical Support

Ongoing technical support for any problems and questions that may arise.

learn more

Factory Inspection and Overhaul

Are you going to keep the turbine running for another ten years, or is it time to replace it?

learn more

Technical Adjustments

Adapt your turbine to meet the changing demands of your production process.

learn more

The Shortest Path to Us, Our Service, and Your Turbine Solutions.

Let our experts advise you individually and without obligation.

Together we will maximise your energy potential.